Anti-Corrosion Prefabricated Steel Structure Poultry Chicken House (KXD-CH1501)

Basic Info

Model No.: KXD-CH1501

Product Description

Model NO.: KXD-CH1501 Usage: Villa, Dormitories, Temporary Offices, Holiday House, Hotel, Prefab House Customized: Customized Roof/Wall Cladding: Fiberglass Wool Sanwich Panel Connect: Bolt Window: PVC or Aluminium Alloy Coating: Hot-DIP Galvanized Trademark: KXD Specification: SGS / ISO HS Code: 9406000090 Material: Steel Structure Certification: ISO, SGS Size: According to Customers′ Requirement Main Steel Frame: Steel Tube Truss System Grade: Q235B Door: Secuirity Door Delivery Port: Qingdao Port Transport Package: Seaworthy Package for Living Container House Origin: China Anti-Corrosion Prefabricated poultry chicken house

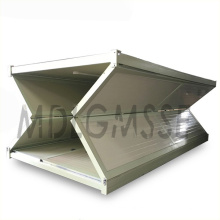

Main Structure

(Steel tube truss system)we adopt hot-dip galvanizing C section or steel tube truss beam to reduce self-weight of design load and dosage of the steel. At the same time, hot-dip galvanized can widely improve anti-corrosion of the steel. (The construction cycle of the steel structure work is short, which reduces the cost of the project effectively. The steel structure has strong shock resistance and can improve the comprehensive anti-seismic property of the whole house).

Substructure(Cold-formed thin-walled steel)

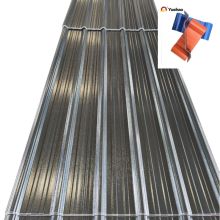

Roof purlin uses the hot-dip galvanized Z or C section. The way to continuous lap makes the steel frame as whole. Roof purlin uses the hot-dip galvanized C section steel. All components adopt bolted connection, no welding, which makes the structure overall appearance smooth.

Protecting system

In order to satisfy the protecting material for 20 years, the outside roof is 0.5 mm aluminum zinc color steel plate. To prevent dewing phenomenon, 50 mm aluminum foil glass wool is laid at the bottom of the roof plate (can be customized according to the climatic conditions). To prevent sagging of the fiber wool, the wire mesh is added, which effectively improve the utilization rate of the glass wool insulation and moisture proof. To add ceiling panels below steel trusses and the ceiling panels laid horizontally is composite color plate, which not only improves the overall stability of steel trusses, but also plays a very good thermal insulation effect. The inside and outside walls laid horizontally is hot-dip galvanized color steel plate, which are all used self-tapping screw to connect into a whole, effectively increasing the lateral stability of steel columns. The indoor humidity is relatively large, so a layer of plastic film is added in order to prevent moisture from entering the fiber glass wool.

Basic rules of structure design

1. Design code for steel structure GB50017-2003;

2. Design Specification for Curved Thin-walled Steel Structure GB50018-2002.

Design parameters

1. Coefficient for importance of a structure is 0.95. The usage life is 25 years;

2. 3 security level;

3. Seismic fortification categories: C-class;

4. Earthquake-resistant level: the main structure is level four.

Structural design load

Uniformly distributed load standard values:KN/m2

1. YX-980 0.5mm outsider roof aluminum-zinc steel plate: ------------------0.049KN/m2;

2. 16kg/m3 50mm heat-insulating fiber glass wool:----------0.008 KN/m2;

3. Z or C roof purlin:-----------------0.034 KN/m2;

4.Roof live load:----------------------0.5 KN/m2.

Concentrated load:KN/m2(3mis a lifting point)

1. Waterline -----------------------0.11 KN/m2;

2. Feed line ----------------------0.22 KN/m2;

3. Motor(the end of waterline and feed line)--------------------0.41 KN/m2;

4. Full load of hopper ------------------------1 KN/m2;

5. Main feed line ------------------------0.18 KN/m2;

6. Wind load ------------------------0.6 KN/m2;

7. Snow load ------------------------0.5 KN/m2.

Material

Load-bearing structural steel (steel column, steel beam) usually adopt Q235 and Q345. According to machinery performance and chemical composition, Steel should be Q235B which conforms to the requirement of current national standard high strength low alloy structural steel (GB/T1591-94) and (GB1591-88).

The ration of the steel tensile strength and yield strength measured value should not be less than 1.25, and there is obvious yield level. Elongation should be more than 20%, and has good weld ability and qualified impact toughness.

The bolt material

1. General bolts can be made by Q235 grade A steel which conforms to the current national standard carbon structural steel. Also, they should conform to the current national standard hexagon head bolts - C and hexagon head bolts - class A and class B.

2. Anchor bolts are made by Q235 steel according to the current national standard--carbon structural steel.

Design value of steel strength

1.Q235(thickness or diameter Contact us if you need more details on Steel Building. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Poultry House、Prefabricated Building. If these products fail to match your need, please contact us and we would like to provide relevant information.

Main Structure

(Steel tube truss system)we adopt hot-dip galvanizing C section or steel tube truss beam to reduce self-weight of design load and dosage of the steel. At the same time, hot-dip galvanized can widely improve anti-corrosion of the steel. (The construction cycle of the steel structure work is short, which reduces the cost of the project effectively. The steel structure has strong shock resistance and can improve the comprehensive anti-seismic property of the whole house).

Substructure(Cold-formed thin-walled steel)

Roof purlin uses the hot-dip galvanized Z or C section. The way to continuous lap makes the steel frame as whole. Roof purlin uses the hot-dip galvanized C section steel. All components adopt bolted connection, no welding, which makes the structure overall appearance smooth.

Protecting system

In order to satisfy the protecting material for 20 years, the outside roof is 0.5 mm aluminum zinc color steel plate. To prevent dewing phenomenon, 50 mm aluminum foil glass wool is laid at the bottom of the roof plate (can be customized according to the climatic conditions). To prevent sagging of the fiber wool, the wire mesh is added, which effectively improve the utilization rate of the glass wool insulation and moisture proof. To add ceiling panels below steel trusses and the ceiling panels laid horizontally is composite color plate, which not only improves the overall stability of steel trusses, but also plays a very good thermal insulation effect. The inside and outside walls laid horizontally is hot-dip galvanized color steel plate, which are all used self-tapping screw to connect into a whole, effectively increasing the lateral stability of steel columns. The indoor humidity is relatively large, so a layer of plastic film is added in order to prevent moisture from entering the fiber glass wool.

Basic rules of structure design

1. Design code for steel structure GB50017-2003;

2. Design Specification for Curved Thin-walled Steel Structure GB50018-2002.

Design parameters

1. Coefficient for importance of a structure is 0.95. The usage life is 25 years;

2. 3 security level;

3. Seismic fortification categories: C-class;

4. Earthquake-resistant level: the main structure is level four.

Structural design load

Uniformly distributed load standard values:KN/m2

1. YX-980 0.5mm outsider roof aluminum-zinc steel plate: ------------------0.049KN/m2;

2. 16kg/m3 50mm heat-insulating fiber glass wool:----------0.008 KN/m2;

3. Z or C roof purlin:-----------------0.034 KN/m2;

4.Roof live load:----------------------0.5 KN/m2.

Concentrated load:KN/m2(3mis a lifting point)

1. Waterline -----------------------0.11 KN/m2;

2. Feed line ----------------------0.22 KN/m2;

3. Motor(the end of waterline and feed line)--------------------0.41 KN/m2;

4. Full load of hopper ------------------------1 KN/m2;

5. Main feed line ------------------------0.18 KN/m2;

6. Wind load ------------------------0.6 KN/m2;

7. Snow load ------------------------0.5 KN/m2.

Material

Load-bearing structural steel (steel column, steel beam) usually adopt Q235 and Q345. According to machinery performance and chemical composition, Steel should be Q235B which conforms to the requirement of current national standard high strength low alloy structural steel (GB/T1591-94) and (GB1591-88).

The ration of the steel tensile strength and yield strength measured value should not be less than 1.25, and there is obvious yield level. Elongation should be more than 20%, and has good weld ability and qualified impact toughness.

The bolt material

1. General bolts can be made by Q235 grade A steel which conforms to the current national standard carbon structural steel. Also, they should conform to the current national standard hexagon head bolts - C and hexagon head bolts - class A and class B.

2. Anchor bolts are made by Q235 steel according to the current national standard--carbon structural steel.

Design value of steel strength

1.Q235(thickness or diameter Contact us if you need more details on Steel Building. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Poultry House、Prefabricated Building. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Poultry House

Premium Related Products

Other Products

Hot Products

Light Steel Structure Villa in AfricaInsulated Prefabricated Building with Ce CertificationCorrugated Color Steel Sheet (KXD-CSS1)Steel Structure Painted C Section Purlin (KXD-C2)Steel Structure Poultry Bird House /Chicken House (KXD-PCH2)Prefabricated Steel Structure Building for Garage and WarehousePrefabricated Modular Container House with Ce CertificationAgricultural Grain Storage Steel Structure Warehouse (KXD-pH9)Good Insulation Prefab House for AccommodationPrefabricated Steel Structure Frame Workshop Building (KXD-SSW9)Modular Prefabricated Mobile House Building for Various PurposesPortal Frame Prefabricated Steel Structure Warehouse (KXD-SSW5)Prefabricated Light Steel Structure Building (KXD-SSB1)Steel Structure Prefabricated Movable House (KXD-PH8)Structural Steel Prefabricated WarehouseStructural Steel Prefabricated Workshop